SASS® 4000

High-Volume Aerosol Concentrator

What is a Concentrator?

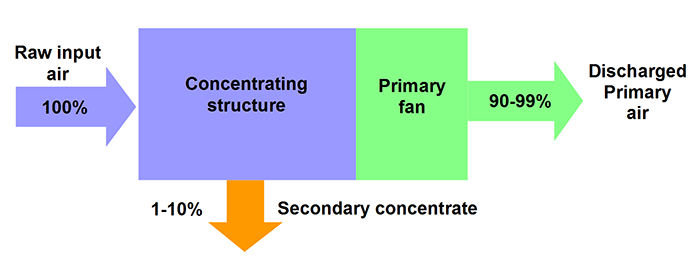

A concentrator processes large volumes of ambient air, continuously transferring particulates from this primary air stream to a much smaller secondary air flow (Figure 1). As a result, the secondary flow can reach aerosol concentrations that are 4X to 15X higher than present in the incoming air. The concentrator therefore amplifies the ambient aerosol concentration, while retaining most of the particles that were present in the incoming air flow in the secondary flow.

Particles are routed into the secondary flow by forcing primary circuit air to circulate through specially shaped channels where centrifugal force and particle momentum are used to isolate and concentrate the particles. The interior structure has been designed so that the smallest flow cross-section is a channel 0.6 mm wide x 6.35 cm long, providing good resistance to clogging by larger particles. A coarse screened cover with 5.4 mm square openings further restricts the entrance of large debris.

Air Flow Patterns

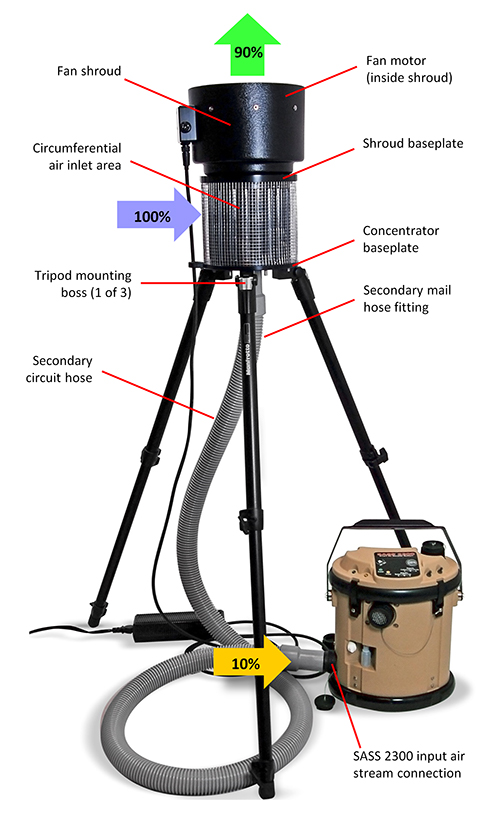

Air flow patterns are shown schematically in Figure 2. Air flows radially inward into the concentrator through the coarse square-mesh screen previously mentioned. This inward radial flow provides 360 degree sampling of the surrounding aerosol environment. A quick-release tripod that is standard with the product allows the preconcentrator section to be located from about 0.6m to 1.43m above the tripod mounting surface.

The primary fan and a curved air shroud are mounted above the concentrator, channeling exhaust air into a vertical stream away from the input air areas. The secondary concentrate air is available at a hose barb fitting designed nominally for 3.8 cm ID hose. This allows the discharged aerosol concentrate to be delivered, with minimum tubing length, to an assay system or wet collector that is on the ground under the concentrator. We recommend that the aerosol concentrate be delivered to its destination using a smooth-surfaced tube of not less than 3.5 cm ID and length not to exceed 3 meters- 2 meters is preferable.

Any sudden change in the aerosol concentrate tube’s cross-section is to be avoided to minimize particle loss to the tube wall, and excessive pressure drop. Tube bend radii should also be of the maximum possible radius to minimize secondary circulation patterns and particle collisions with the tube wall.

Collection Blades

The particulate concentration process is primarily performed within 20 rectangular collection ‘blades’ that slip into radial slots in the main structure (Figure 3). These blades are precisely formed to the desired shape using state-of-the-art CNC machining centers. This manufacturing method assures that air moves as intended within the interior channels and minimizes particle loss through wall collisions, while also minimizing the overall pressure difference required to push air through the device.

Performance

Figure 4 shows typical data for concentration factor as a function of particle size for a primary air flow of about 3000-3600 LPM and secondary air flow of 300 LPM. This Figure is based on tests that used fluorescent polystyrene microspheres (density=1.05 g/cc) and fragments thereof, as test particles. Concentration factors were determined from multiple test runs using a Met One 200L laser particle counter.

The Figure shows that aerosols of this density and with effective optical diameters in the range of 0.5 to 1.0 microns were concentrated by a factor of 3X to 4X. Particles in the range of 1.0 to 2.0 microns were concentrated by a factor of 4X to 5X, while larger respirable particles were concentrated by a factor of about 6X.

Particle concentrations in the secondary flow can be further enhanced by reducing the secondary airflow, as shown in Figure 6. For example, at a secondary airflow of about 40LPM, the concentration factor is increased by about 3X relative to operation at 300 LPM. However, please note that the total amount of particulate matter collected begins to fall substantially for secondary airflows below about 200 LPM.

Reduced airflow can be of significant value if the detection method requires small amounts of fluid. For example, CBRN International’s standard air sampler, the SASS 2300, has an airflow of about 300 LPM when connected to the SASS 4000 Concentrator, and operates with a water inventory of about 5 ml. The SASS 2400, however, which has a nominal airflow of 40 LPM, has a liquid inventory of only about 1 ml. Hence, the Mini-SASS may show a concentration increase of about 15X for this example case, as compared to 5X for the SASS 2300. However, the total amount of particulates collected within a fixed period by the Mini-SASS may be only 40% of that collected with the larger wet sampler. Which overall collection strategy is best will depend on application specifics.